The successful convening of the 20th CPC National Congress opened a new journey of Chinese path to modernization. The 2023 government work report clearly proposes to "accelerate the construction of a modern industrial system", which points out the target direction for the textile and chemical fiber industry to further promote high-quality development.

The research activity received positive feedback from key enterprises in the chemical fiber industry. As of July 14th, a total of 93 valid questionnaires were received from enterprises, covering sub industries such as polyester, nylon, recycled cellulose fibers, recycled fibers, spandex, polypropylene, vinylon, high-performance fibers, and bio based fibers, with strong universality and representativeness. After summarizing, organizing, and comprehensively analyzing the collected questionnaires, this report is prepared to provide reference for governments, institutions, industries, enterprises, etc. to grasp the characteristics and key concerns of industry operation and development trends, research and analyze the future key development directions of the industry, formulate macro policies and development strategies, and other aspects.

1、 The industry is showing a gradual recovery trend, and efforts need to be made to expand downstream demand.

Since 2023, the production growth rate of the chemical fiber industry has gradually increased, but the recovery on the demand side is less than expected. In addition, the cost of raw materials has been squeezed, and the overall production and operation situation of the industry is still severe.

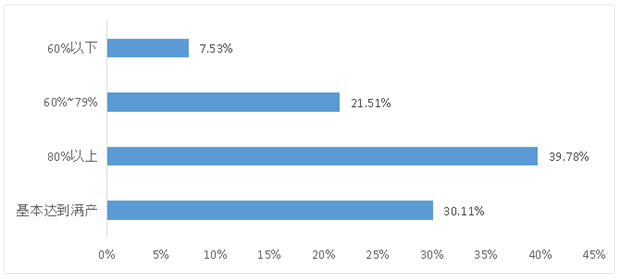

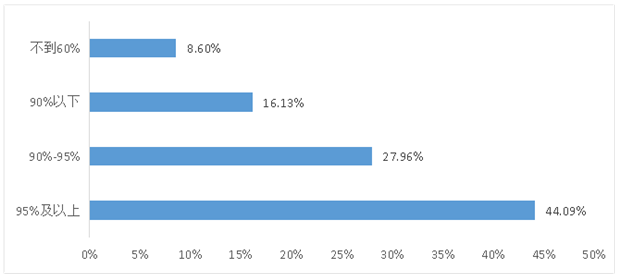

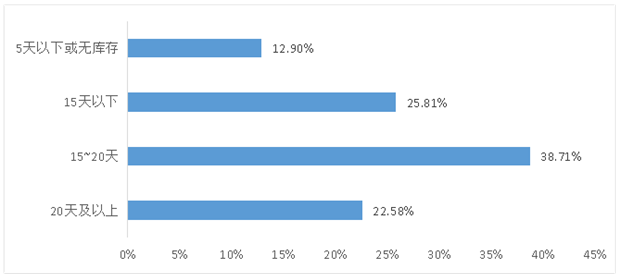

1. The overall operating load of the industry was better than the same period last year, and the domestic sales market improved in the second quarter. In addition, the export growth rate was significant, and the inventory of major products was generally at a normal level. According to the feedback from the questionnaire survey, from January to April, the proportion of sample enterprises with an overall operating load of over 80% was 69.79%, the proportion of enterprises with a production and sales rate of over 90% was 72.05%, and the proportion of enterprises with inventory below 20 days was 77.42%. It can be seen that the industry's production and sales situation is basically stable, and the inventory situation is basically good (Figure 1- Figure 3). Compared to the same period in 2022, the production and sales of the chemical fiber industry are showing a recovery trend.

Figure 1: Starting Load of Sample Enterprises from January to April 2023

Figure 2 Production and sales rate of sample enterprises from January to April 2023

Figure 3 Inventory situation of sample enterprises from January to April 2023

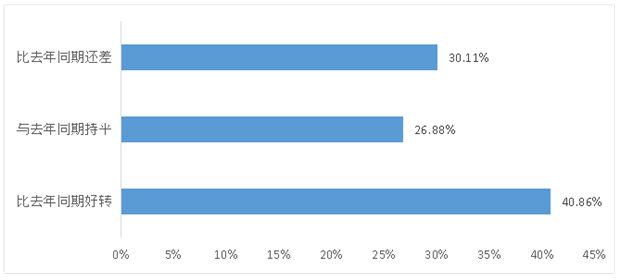

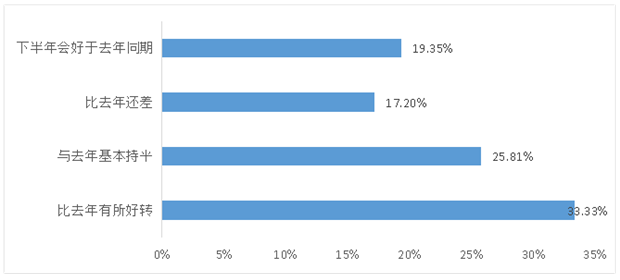

2. The confidence of enterprises in the recovery of the textile and chemical fiber industry chain needs to be strengthened. The survey questionnaire shows that for the market situation from January to April 2023, 40.86% of companies believe that there has been an improvement compared to the same period last year, 26.88% of companies believe that it is on par with the same period last year, but 30.11% of companies believe that it is still worse than the same period last year (Figure 4); For the chemical fiber market situation for the entire year of 2023, only 33.33% of enterprises expect the market operation to improve compared to the same period last year, and only 19.35% of enterprises expect the market operation to improve in the second half of the year compared to the same period last year (Figure 5).

Figure 4 Market situation of sample enterprises from January to April 2023

Figure 5 Sample Enterprises' Expectations for the Full Year 2023 Chemical Fiber Market

From the production and operation difficulties reported by the sample enterprises, the main reasons for the lack of market confidence of the enterprises are as follows: firstly, the recovery of terminal demand is not as expected, especially the high inventory in the European and American markets, which leads to a decrease in downstream order volume and affects the sales of upstream raw materials; Secondly, the international situation is complex and ever-changing, with significant fluctuations in raw material prices, coupled with poor downward transmission of prices, resulting in continuous pressure on the cost side; Thirdly, some industries have added a lot of new production capacity, and structural overcapacity in some fields has become an unavoidable problem at the current stage, compressing the economic benefits of enterprises through homogeneous competition; Fourthly, there are relatively few products with strong competitiveness and high added value, and the premium ability is insufficient; Fifth, international trade frictions continue, and anti-dumping and countervailing incidents targeting China's chemical fiber product exports have reduced its export competitiveness; The sixth is the increase in labor costs, resource factors, and the sharp increase in the cost of coal to gas, leading to an increase in production costs; Seventh, small and medium-sized enterprises are relatively difficult to obtain credit and are prone to difficulties in capital turnover.

3. Research has found some common problems in the operation of the industry, providing key directions for further improving industry service work. One is to integrate industry innovation resources, guide enterprises to carry out technological innovation, management innovation, institutional innovation, and mechanism innovation, and continuously improve their competitiveness; The second is to strengthen policy support and guide enterprises to transform and develop towards high-end, intelligent, and green technologies, such as providing more incentive policies for the introduction of high-end technical talents and product innovation, and encouraging and promoting the key application of new technologies and products; Thirdly, we will continue to strengthen the policy of expanding domestic demand, and the industry should organize diverse consumer promotion activities to further boost terminal consumption and guide green consumption; Fourth, provide more support for product exports, such as guiding enterprises to form groups to "go global", participate in more overseas related exhibitions, and strive for more orders; Fifth, provide more financial support to the real economy, such as strengthening credit guarantees, increasing direct financing, especially improving the problem of difficult and expensive credit for small and medium-sized enterprises; Sixth, continue to increase the efforts to reduce taxes and fees, and reduce the costs of energy and labor for enterprises; Seven is to guide enterprises to invest cautiously and promote self-discipline and sustainable development in the industry, such as playing a good role in guiding the "Analysis of Investment Sensitivity in the Chemical Fiber Industry (2023 Edition)" to avoid blind expansion of enterprises; Eight is to accelerate the orderly exit of outdated production capacity, with a focus on supporting the application of advanced technology devices and low energy consumption equipment.

2、 Collaborative innovation in the industrial chain and the introduction of high-end technical talents have become important focus points for enterprise technological innovation.

After years of development, the technological strength of China's chemical fiber industry has significantly increased, and the technological level has entered a new stage of gradually moving from being a follower to running alongside the world's leading level, providing strong support for China's economic development, improving people's livelihoods, ecological optimization, and national security. At the same time, the new capacity of the industry is constructed at a high-tech level. The progressiveness, capacity scale, energy consumption, and integration level of the new devices bring certain cost and technical advantages to promote the improvement of the industry's production level and capacity structure adjustment.

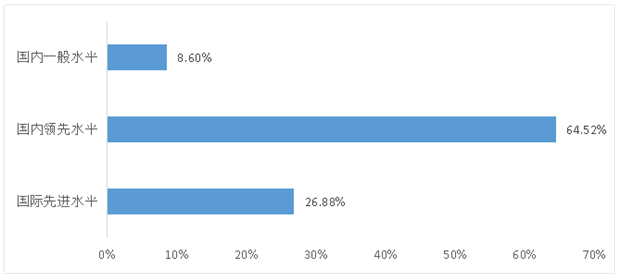

1. The overall production technology and equipment level in the current industry is relatively high. According to the feedback from the questionnaire survey, 64.52% of the sample companies believe that their current production technology and equipment level is at the leading level in China, 26.88% of the sample companies believe that their current production technology and equipment level is at the international advanced level, and only 8.60% of the sample companies believe that their current production technology and equipment level is at the average level in China (Figure 6).

Figure 6 Current Production Technology and Equipment Level of Sample Enterprises

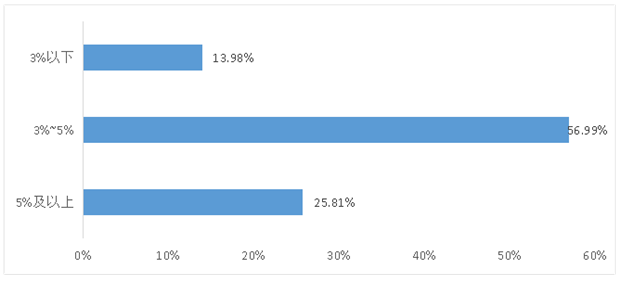

2. The research and development investment intensity of the surveyed enterprise is significantly better than that of the entire industry. The survey questionnaire shows that 56.99% of the sample enterprises' R&D investment accounts for a proportion of 3% to 5% of their main business income, mostly enterprises in traditional industries that mainly focus on differentiated varieties; 25.81% of the sample enterprises have R&D investment accounting for over 5% of their main business income, mainly composed of high-performance fiber and bio based fiber enterprises; 13.98% of the sample enterprises' R&D investment accounts for less than 3% of their main business income (Figure 7).

Figure 7: R&D investment intensity of sample enterprises in 2022

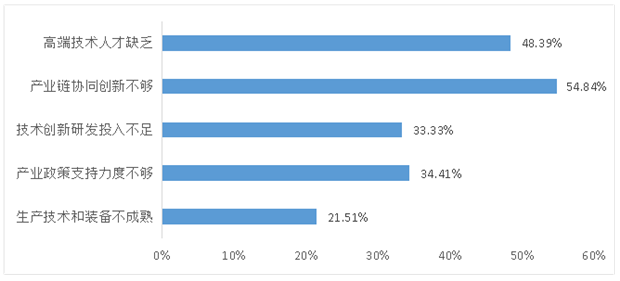

There are many reasons that currently constrain technological innovation in the industry, but they are relatively concentrated. According to the survey questionnaire, 54.84% of the sample companies believe that there is insufficient collaborative innovation in the industrial chain, while 48.39% of the sample companies believe that there is a lack of high-end technical talents (Figure 8). Both of these factors account for a relatively high proportion, which indirectly reflects the two key points for the industry to further promote technological innovation. In addition, 34.41% believe that the support of industrial policies is insufficient, and 33.33% believe that investment in technological innovation and research and development is insufficient.

Figure 8: The main reasons currently restricting technological innovation in the industry

In fact, both the Chemical Fiber Association and enterprises have made many practical actions in technological innovation and product research and development. As an important extension of China's fiber trend, the Fiber Road - China Fiber Trend Matching and Exchange Activity was launched in 2021. Over the past two years, chemical fiber enterprises have been organized to communicate and connect with nearly 20 clothing brand enterprises, effectively building a bridge for upstream and downstream communication and assisting in collaborative innovation of the industrial chain. The joint construction of research and development bases by the Chemical Fiber Association and enterprises focuses on promoting product research and technological progress in the industry, leading collaborative innovation in the industry. The National Advanced Functional Fiber Innovation Center, led by Shenghong Group, fully integrates the power of "industry, academia, research and application", focuses on tackling key core technologies, and breaks through development bottlenecks. Leading enterprises such as Tongkun Group, Hengyi Group, and Huafeng Chemical have established their own research institutes, introduced high-end technical talents, vigorously carried out basic research and "bottleneck" technology research, and continuously promoted industrial transformation and upgrading.

4. The main directions for technological equipment research and product development. In a fiercely competitive market, competition for quality and differentiation will always accompany industry development, thereby promoting the continuous research and development of high value-added and functional varieties of chemical fibers. Green manufacturing and intelligent manufacturing are the trend of the times, and the expansion and cross-border integration of application fields represented by fiber new materials and industrial applications are also the top priorities for the technological development of the chemical fiber industry. According to the feedback from the survey questionnaire, the main directions for the next step of technological equipment research and product development of the sample enterprises also confirm these trends.

In terms of technology and equipment research and development, the main focus is on continuously promoting the high-end and intelligent development of key technology and equipment, and improving the level of production management; Realize stable operation of domestically produced replacement of key equipment such as winding heads, and improve autonomous and controllable capabilities; Upgrade the technology of existing equipment, with a focus on promoting energy-saving and consumption reduction transformation; Increase investment in the research and development of key technological equipment in the fields of large and small varieties, high-performance fibers, and bio based fibers, leading the forefront of technology.

In terms of product research and development, the main focus is on vigorously developing differentiated and functional products, optimizing product structure, improving product quality, continuously meeting downstream diversified needs, and enhancing corporate brand influence with high value-added products; Based on the main business, while extending the industrial chain, actively exploring the research and development of materials and customized production in fields such as intelligent wear, big health, and filter materials; Taking green and low-carbon as the core, we will carry out technological breakthroughs around bio based and degradable polyester, recycled chemical fibers, functional polyester, functional masterbatches, green catalysts, etc.

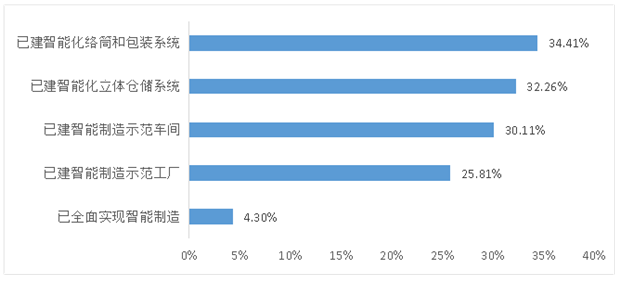

5. Intelligent manufacturing in the chemical fiber industry has achieved many achievements. There are significant differences in the level of intelligent manufacturing in the industry among the surveyed enterprises. The survey questionnaire shows that intelligent manufacturing in the chemical fiber industry is still mainly reflected in the establishment of automatic winding packaging systems, three-dimensional storage systems, as well as the establishment of intelligent manufacturing demonstration workshops and factories. Among them, 25.81% of the sample enterprises have built intelligent manufacturing demonstration factories, 30.11% have built intelligent manufacturing demonstration workshops, 32.26% have built intelligent three-dimensional storage systems, and 34.41% have built intelligent winding and packaging systems (Figure 9). It should be noted that there are four companies that have chosen to fully implement intelligent manufacturing, which may be due to a discrepancy in the understanding of "fully implementing intelligent manufacturing" by the filling out personnel.

Figure 9: The level of intelligent manufacturing in sample enterprises

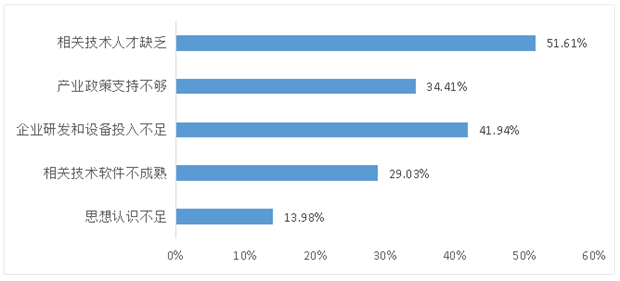

For the main reasons that currently constrain the industry's intelligent manufacturing, the survey questionnaire shows that 51.61% of the sample companies believe that it is a lack of relevant technical talents, 41.94% of the companies believe that it is due to insufficient R&D and equipment investment, 34.41% of the companies believe that it is due to insufficient industrial policy support, 29.03% of the companies believe that it is due to the immaturity of relevant technical software, and 13.98% of the companies believe that it is due to their own lack of ideological understanding (Figure 10).

Figure 10: The main reasons currently restricting intelligent manufacturing in the industry

At present, most chemical fiber enterprises have recognized that intelligent manufacturing is an important support for the transformation and upgrading of traditional industries. By actively exploring and practicing advanced technologies and concepts such as big data, Internet plus, cloud platform, industrial robots, artificial intelligence, etc., we will promote the in-depth application of modern information technologies such as ERP, MES, etc. in the design, production, marketing, logistics and other links of the chemical fiber industry, and promote the flexible, intelligent and refined development of the production model. The chemical fiber industry has been in the application of automation equipment, the construction of intelligent workshops/factories Good results have been achieved in areas such as automated warehousing and logistics, and the construction and application of a batch of intelligent manufacturing demonstration projects have effectively improved the level of intelligent manufacturing in the industry.

In the future, at the government level, we need to increase financial support and fully leverage the guiding role of fiscal funds; Provide tax incentives and insurance compensation policies, and open up a major investment green channel for implementing intelligent manufacturing; Encourage the flow of financial, human, land and other essential resources to advanced intelligent manufacturing enterprises. At the industry level, it is necessary to actively carry out intelligent manufacturing demonstration engineering technology exchanges; Strengthen the leadership in cultivating typical demonstration enterprises and carry out intelligent manufacturing technology talent training; Develop industry standards for intelligent manufacturing; Build an intelligent manufacturing industry alliance and coordinate the role of core technology innovation resources in the industry. At the enterprise level, we need to continue to increase investment in automation and intelligence, focus on the entire industrial chain of design, production, logistics, sales, and services, accelerate the application of digital technology, and fully achieve machine replacement in individual processes; Improve the core big data integration and application capabilities of enterprises in areas such as intelligent devices, interconnectivity, system integration, and resource optimization, and gradually build enterprise intelligent production lines, intelligent workshops, and intelligent factory systems.

3、 Green development has become the core concern of the chemical fiber industry, and some enterprises have taken the forefront in their understanding and actions towards sustainable development.

With the increasingly strict national environmental protection policies and the continuous enhancement of social environmental awareness, the chemical fiber industry has actively carried out energy-saving, carbon reduction, and green technology transformation, accelerated the construction of green manufacturing systems, and has achieved good results.

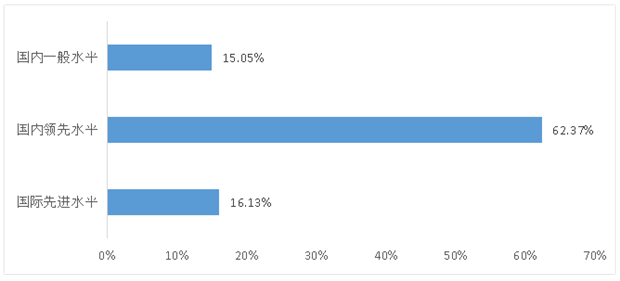

1. Currently, the overall level of green production technology and equipment in the industry is at the leading level in China. According to the feedback from the questionnaire survey, 62.37% of the sample companies believe that their current green production technology and equipment level is at the leading level in China, 16.13% of the companies believe that their current green production technology and equipment level is at the international advanced level, but 15.05% of the companies still believe that their current green production technology and equipment level is at the average level in China (Figure 11).

Figure 11 Green production technology and equipment level of sample enterprises

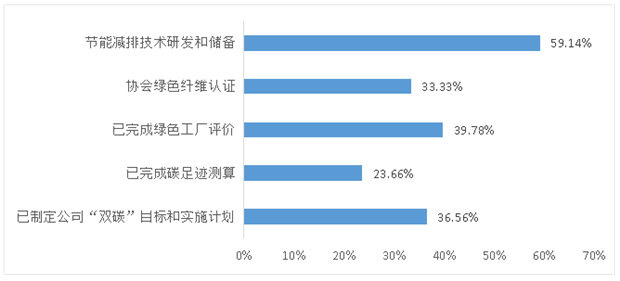

2. Significant progress has been made in the green transformation of the industry. Promoting green and low-carbon circular development and promoting comprehensive green transformation has become an important strategy for the industry, and sustainable development is crucial for the operation of enterprises. According to the survey questionnaire, 59.14% of sample enterprises have carried out research and development and reserves of energy-saving and emission reduction technologies, 39.78% of sample enterprises have completed green factory evaluation, 36.56% of sample enterprises have formulated company "dual carbon" goals and implementation plans, 33.33% of sample enterprises have carried out association green fiber certification, and 23.66% of sample enterprises have completed carbon footprint calculation (Figure 12). The specific work includes: adopting efficient and energy-saving production processes, promoting clean production, establishing full process digital control, and deepening green full lifecycle management; Focus on tackling green and low-carbon technologies, and increase the research and application of biodegradable, renewable, and recyclable fiber materials; Pay attention to the recycling and utilization of energy resources, replace traditional energy with renewable energy such as hydropower, wind power, and optoelectronics, and increase the utilization rate of green energy; Develop "dual carbon" goals, carry out information disclosure, implement emission reduction plans, and launch a "zero carbon" product development plan.

Figure 12: The status of green development related work completed by sample enterprises

The green fiber certification work carried out by the China Chemical Fiber Association has achieved good results. This certification includes three categories of green fibers and their product certifications: bio based chemical fibers, recycled chemical fibers, and raw liquid colored chemical fibers. Based on a complete set of advanced standards, it has green and low-carbon requirements for the production process, raw and auxiliary materials, and product quality. It can provide reliable services for consumers, manufacturers, and brands. This is a powerful exploration of China's independent certification system for textile and chemical fibers, Committed to providing a new solution for the chemical fiber material industry chain that has a positive impact on global climate change.

It is worth noting that under the leadership of the CV Alliance, the regenerated cellulose fiber industry has taken the lead in understanding and actions towards sustainable development in the entire industry. Multiple CV alliance enterprises have started to systematically promote the construction of sustainable management systems, and have made substantial progress in the enterprise's "dual carbon" goals, closed-loop clean production, sustainable development report preparation, product carbon footprint tracing, sustainable brand design, and other aspects. They have established a wide influence in the domestic and foreign textile industry chain and end markets. These experiences are worth learning from throughout the industry.

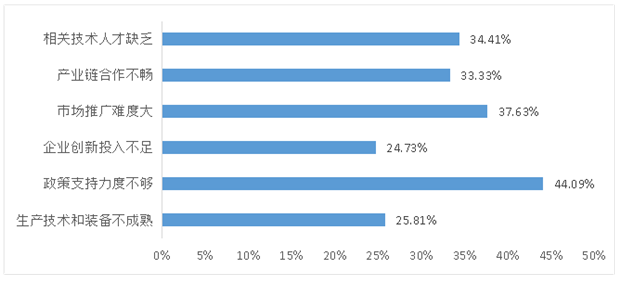

There are many reasons currently restricting the green development of the chemical fiber industry. According to the survey questionnaire, 44.09% of the sample companies believe that policy support is insufficient, 37.63% of the sample companies believe that market promotion is difficult, 34.41% of the sample companies believe that there is a lack of relevant technical talents, and 33.33% of the sample companies believe that the cooperation in the industrial chain is not smooth (Figure 13). In addition, about 1/4 of enterprises believe that their production technology and equipment are immature, and their innovation investment is insufficient.

Figure 13: The main reasons currently restricting the green development of the industry

Correspondingly, in order to further promote the green development of the industry, it is necessary to gather various resources such as policies, markets, technology, talents, etc., such as increasing policy support, strengthening financial support such as industrial transformation and upgrading funds, special construction funds, green credit, and local funding support, and continuously promoting green design products, green factories, green industrial parks, and green supply chain management; Strengthen green promotion, advocate resource recycling, green and low-carbon lifestyle, and guide green consumption; Conduct basic research, encourage green technology transformation, and further promote the construction of a green manufacturing system; Collaborate with upstream and downstream enterprises in the industrial chain to promote the use of green fiber products and enhance the recognition of green fiber certified products.

4、 The deepening adjustment of the world economic landscape has brought new industrial issues, which require coordinating industry development and industry security, and enhancing the resilience of the industrial system to shocks.

At present, the world is in a major upheaval that has not been seen in a century. The impact of the pandemic in the 21st century is far-reaching, and the trend of anti globalization is rising. Unilateralism and protectionism are clearly rising, and the global industrial and supply chains are reshuffled. The world economic landscape has undergone profound changes. Focusing on ensuring national security, public safety, industrial safety, etc., major economies in the world will inevitably prioritize policy adjustments based on their own interests. In this new round of adjustment, the restructuring of the global industrial landscape is bound to trigger the reshaping of international rules.

According to the feedback from the survey questionnaire, 54.84% of the sample companies believe that the intensification of international trade friction in products is the main issue facing the industrial security of the chemical fiber industry (Figure 14). In recent years, the export volume of China's chemical fiber products has gradually increased, and there have been frequent anti-dumping and countervailing incidents against their exports. Recently, India's BIS certification involves some polyester products, which has also had a certain impact on chemical fiber exports. Therefore, it is even more necessary to be vigilant against international trade frictions and trade barriers to maintain stable growth in export market share.

23.66% of enterprises choose to rely on imports for key technology and equipment, with incomplete industrial chain support. 19.35% choose key technology and equipment, components or products that have import restrictions, and 18.28% choose single raw material sources and technical routes. These are also the main factors affecting the stable and safe development of the chemical fiber industry. This is also basically consistent with the bottleneck technology and shortcomings that currently constrain the development of the industry, and is also a top priority for strengthening the security of the chemical fiber industry at present and in the future.

Figure 14 Main Issues Faced by Industry Security in the Current Industry

The deepening adjustment of the world economic pattern has brought new industrial issues, facing many factors that affect industrial security. It is necessary to coordinate development and security, enhance the impact resistance of the industrial system, such as strengthening the research and development of key technology and equipment, strengthening the supply chain and extending the supply chain, encouraging, guiding, and supporting the application and substitution of domestic materials; Based on the "dual circulation" pattern, expand application traction, and improve industrial chain coordination and linkage; Strengthen international exchange and cooperation, participate in leading the formulation of major country trade rules, and enhance its position in international division of labor; Pay attention to changes in the international situation, cooperate with the pace of downstream industry transfer, and do a good job in expanding overseas markets; Establish an early warning mechanism to prevent risks such as abnormal international capital flows, data network security, geopolitical risks, and international trade frictions.

5、 Enterprise development requires a group of versatile talents who understand technology, cross industry chains, markets, and management.

With the increasingly strong innovation atmosphere in the industry, the position and role of talents as the main body of innovation are becoming increasingly prominent. The survey shows that enterprises generally attach great importance to talents, especially high-end technical talents, senior marketing talents, and senior management talents.

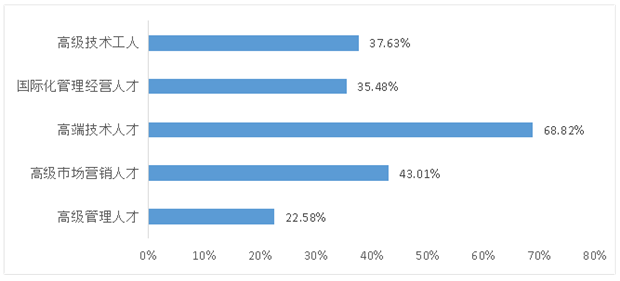

The urgent demand for high-end technical talents in enterprises is * * *. According to the feedback from the questionnaire, up to 68.82% of the sample enterprises have a demand for high-end technical talents, which also confirms that introducing high-end technical talents has become an important focus of enterprise technological innovation as mentioned earlier. In addition, 43.01% of the sample enterprises have a demand for advanced marketing talents, and 35.48% of the sample enterprises have a demand for international management and operation talents (Figure 15), indicating that the development of enterprises requires a group of composite talents who understand technology, not only in this field but also across industry chains.

Figure 15: Demand for Senior Talents in Sample Enterprises

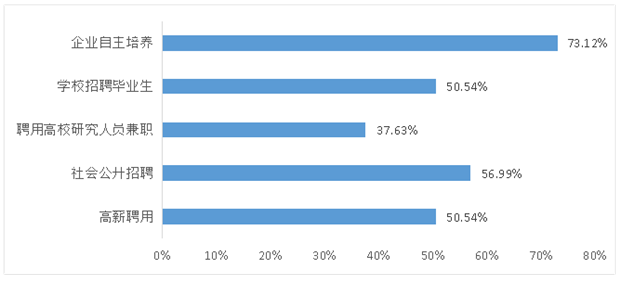

2. Enterprises mainly cultivate talents independently, and social employment (including high-tech employment) and recruitment of graduates are also the main methods. In terms of the channels for enterprises to obtain talent, the survey questionnaire shows that 73.12% of the sample enterprises choose independent training methods, while over 50% of the sample enterprises choose methods such as public recruitment, school recruitment of graduates, and high salary recruitment, making them the main source of talent for current enterprises. In addition, 37.63% of the sample companies choose to hire university researchers part-time (Figure 16).

Figure 16 Main channels for sample enterprises to obtain talent

The chemical fiber industry is the core support for the stable development and continuous innovation of the textile industry chain, an internationally competitive advantage industry, and an important component of the new materials industry. How to cultivate innovative, professional, and versatile talents is an important issue related to the high-quality development of the industry. In the future, the industry needs to improve the concept, system, mechanism, path, resources, etc. of talent cultivation, follow the laws of talent growth and scientific research activities, and attract, retain, and make good use of talents. Improve the work, research, and exchange policies for high-end and professional talents, and create a competitive and attractive environment for outstanding talents in areas such as salary and benefits, children's education, and social security; At the same time, we need to increase the design of channels for the development of technical talents and the establishment of incentive mechanisms.

In terms of talent cultivation and motivation, the China Chemical Fiber Association has made a lot of exploration and practice. The "National Advanced Training Course for Textile Composite Talent Cultivation Project" focuses on cultivating composite management talents. Since its opening in 2015, it has successfully held seven sessions, and has now formed a complete industry chain education system from textile raw materials to mechanical equipment, from fiber production to yarn weaving, from fabric research and development to terminal brands; The "China Chemical Fiber Industry Association Hengyi Fund" Outstanding Science and Technology Talent Award focuses on recognizing high-end technical talents, promoting the spirit of craftsmanship, and promoting technological progress.

In the future, the chemical fiber industry will also focus on strengthening various types of talent cultivation, continuing to improve the school enterprise joint innovative talent cultivation model, and focusing on cultivating skilled talents guided by market demand; By collaborating with different organizations such as brands, testing, and finance, we aim to cultivate versatile talents with an international perspective; Establish various talent exchange platforms in the industry and regularly carry out high-end technical talent exchanges; Establish various talent pools in the industry, carry out talent training and construction in the industry, and enhance the matching between enterprise and talent supply and demand.

(Source: China Chemical Fiber Industry Association)